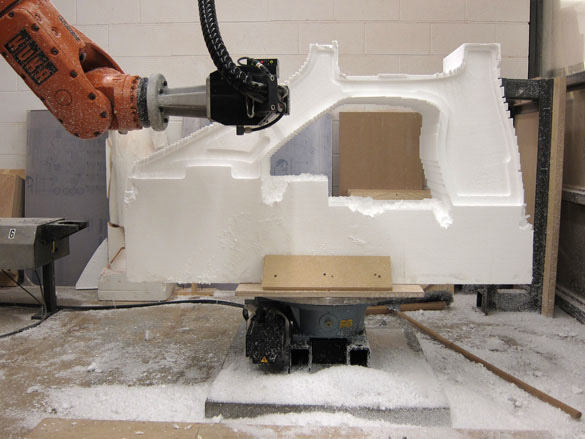

- A seven-axis Kuka robotic mill roughing down a 2lb foam block on the turntable.

- The finished component.

- The same component, nested for 3d plaster printing in an 8"x10"x8" bed.

- Printed components, in the vacuum cleaning bed of the Z-Corp machine.

- Rendered image of a 5-foot tall "buoy" lamp.

- CNC plasma cutting the lamp-shade from a 1/8" sheet of steel.

- Two Roland 3-axis mills working simultaneously.

- The milled maple molds, pre-drilled for vacu-forming.

- Section-elevation of a tension-cable stair railing.

- Fabricating the railing on site using a 110-volt MIG welder.

-